This content was published: August 11, 2014. Phone numbers, email addresses, and other information may have changed.

Student building a better prosthetic hand at PCC’s MakerSpace

Photos and story by James Hill

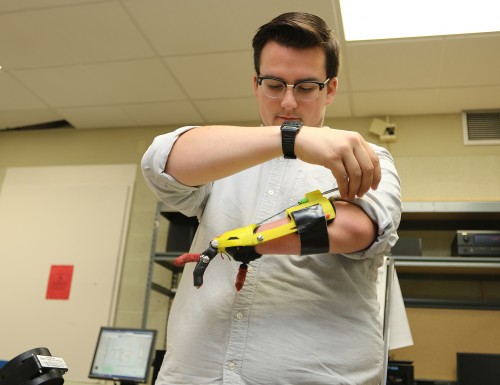

Portland Community College student Jordan Nickerson of Kelso, Wash., is giving himself a hand. Literally.

The 23-year-old first-year computer science major, who was born without much of his left hand, is fabricating his own prosthetic limb that has moving fingers to better grip objects. With a screwdriver and lots of patience, Nickerson has improved upon the hand, which is based on plans and components found in other hand designs. He hopes to perfect his version for production to sell to the world as a cheaper alternative to cumbersome and expensive prosthetics. The model can grasp objects and is made of carbon fiber, ABS and biodegradable corn plastics, Velcro, duct tape and a mouse pad – all at a cost of about $40.

“I have always had a fascination with prosthetics, for obvious reasons since I don’t have a hand,” Nickerson said. “It’s connected by two hinges and I put my arm in the socket and I flex my wrist and the fingers close. All five fingers close at once to make a fist, but with a little bit of tensioning you can make it where the thumb and the index finger touch first so if you wanted to pick up something small, you can.”

With a screwdriver and lots of patience, Nickerson has sculpted several versions of the hand, which he hopes to perfect for production to sell to the world as a cheaper alternative to cumbersome and expensive prosthetics.

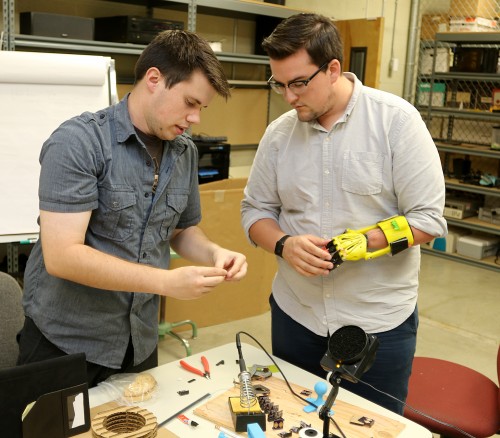

Some of the materials and ideas he used to put the hand together were made by the army of 3D printers in PCC’s MakerSpace – a creative lab located at the Sylvania Campus, 12000 S.W. 49th Ave. MakerSpace, coordinated by engineering faculty Gregg Meyer, is an interdisciplinary innovation studio dedicated to the art and science of making things.

“Yeah, It would have been a whole lot harder and way more expensive without MakerSpace,” Nickerson smiled. “That’s something that MakerSpace really saved money on (supplies and access to machinery).”

MakerSpace provided resources

The MakerSpace movement is a new phenomenon spreading across the nation, including the White House where President Obama hosted his first-ever Maker Faire in June. The purpose of the movement is to increase access to technology and education through open shared spaces with tools and equipment. PCC’s MakerSpace offers an opportunity for staff and students to collaborate and bring ideas to life, a place where budding scientists, technologists, engineers, artists and mathematicians can find common ground to collaborate on cool ideas. They have access to the 3D printers and scanners, CNC machines, lasers, vinyl cutters, sheet metal tools, plastic injection molder and even a sewing machine.

“In just six months of operation the MakerSpace has grown from an engineering prototyping lab to an innovation studio serving students, faculty, and services all across campus,” said Gregg Meyer. “I couldn’t be happier with this progression. Students are getting cool jobs as a direct result of their newly acquired maker skills, faculty members spanning several departments have become friends outside of work, and Design-for-Good projects like hard drive crushers for e-cycling, and human powered watering pumps for our community garden are starting to build steam.

“Jordan is parlaying his ‘disability’ into a new business venture using the MakerSpace to design and fabricate 3D printed prosthetic hands; ones that work and fit better than similar devices costing 100 times as much,” he added. “Now that’s a win-win-win endeavor no matter how you look at it.”

The MakerSpace is funded in part by money from the Intel Corporation.

“Having a multitude of resources at the fingertips of students, that’s exciting,” said Janet Rash, Intel’s Northwest Region Community Engagement Manager. “The Maker Movement has allowed companies like Intel to get more creative in how they try to attract interest in engineering and technology careers. I think when you’re doing things, it’s easier to make the leap to what an engineer might do or a computer scientist might do, and the imagination of a student starts to expand.”

New company in the works

Nickerson, who resides in Northwest Portland, fits the prototypical student Meyer is looking to energize. After a few terms studying computers, he met a man at a networking event that had plans created by Jorge Zuniga for a prosthetic hand that interested him. From there, Nickerson, who plans to transfer to Portland State University when he’s done at PCC, began building the hand from those plans at MakerSpace and elsewhere last May.

PCC’s MakerSpace offers an opportunity for staff and students to collaborate and bring ideas to life, a place where budding scientists, technologists, engineers, artists and mathematicians can find common ground to collaborate on cool ideas.

“I automatically got intrigued with it,” Nickerson said. “I was kind of listening in on his conversation and he whipped out his phone. On it I see the picture and I just walked up to him and asked for it. And that’s essentially how it all started. I saw an opportunity and decided to go with it.”

When the model is refined enough Nickerson plans to market it as the centerpiece of a business plan. He wants to establish a company that builds prosthetic hands on demand through requests he gets from a website and phone app. People would scan their arm and send the measurements to them on email. Nickerson then would print it on 3D printing machines and ship the prosthetic to the customer directly. The cost to the customer he estimates would be $300 and if people buy one he’ll donate another to an impoverished child who needs one.

“If you can afford to buy an Xbox you can afford to buy this hand,” Nickerson said. “The downside with the prosthetic industry is that, when I was a kid, the basic prosthetics were just hooks and they cost around $2,000 to $5,000. And you have to completely manipulate your body to use it. You have to move your shoulder back, throw your elbow forward, and it then opens. It’s super complicated, really annoying and obnoxious to use. And plus its a hook so its kind of intimidating especially when you’re a child.

“With this one, it works with your natural body movement,” he added. “It works on your wrist motion. Since it’s 3D printed it’s extremely lightweight and customizable to that person. Eventually we want to try to reach everyone in the world.”

But for now there are issues as he tries to find the right fit and iron out technical challenges to the hand. “The fingers are kind of a pain in the butt,” he explained, showing off the hyperextended digits.

And he’s quite happy to have found PCC and a space that has spurred his ingenuity.

“I heard that it was one of the best community colleges in the nation so I thought it was a good fit to start out at,” Nickerson added.

[…] Read the full story here. […]

This is an awesome creation. Way to go Jordan! Best of luck in your future ventures.

I am a staff member at Disability Services at PCC. I have two questions:

1. What are the ways Staff, Students, and community members can access the Maker Space at PCC?

2. How do I brainstorm with other Makers about ideas in the PCC community? I am a wheelchair user who is also struggling with an extremely costly, provision and repair system for motorized wheelchairs. I’ve seen people 3d print wheelchair seats for athletes, I’ve seen people 3d print cookie cutter type wheelchairs for developing countries, I’ve seen people use arduino to build open source assistive technology like exoskeletons but I have not seen anyone tackle the manual or motorized wheelchair through the Maker movement with the same zest as robot arms, and prosthetic hands. I’d like to change that but I don’t think I can do it alone. Any advice?

As pointed out by Erik, I too would love to know how community members can access the MakerSpace at PCC. Thank you!

Hello, you can click the MakerSpace link in the story or email makerspace@pcc.edu [opens in new window] for more information on this. Hope this helps!

[…] This article from the Digital Shift covers trends that were emerging in 2013 in libraries throughout the nation. I am really drawn to the idea of maker spaces, and we’ve had great success with one where I work lately. I work at a bookstore, but on a community college campus. One of the students here, utilizing our MakerSpace was able to 3D print himself a prosthetic hand! Read about his amazing story here. […]

Thanks for all your interest! Beginning this Fall term we are going to be hosting “First Fridays” at the MakerSpace for all PCC employees. Hours are still being worked out, but we are envisioning at least four to six hours of staffed open lab time where visitors can get hands on training and work on projects of personal interest.

As staff, faculty and admistrators of PCC, you will also have open access to the lab during all open hours (schedule will be posted on the door and on the website).

Students interested in using the MakerSpace have only to register for MCH 291 (laser) or MCH 292 (3D printing) both of which are self-paced mini courses. This Winter term we also plan to begin offering a Rapid Prototyping and Advanced Manufacturing interdisciplinary certificate, so if anyone is interested in learning more about that please contact me directly at gregg.meyer@pcc.edu [opens in new window].

Last, but not least, the MakerSpace is open this summer MWF 10-2 and T/Th 2-6. There will be cllasses and workshops running on and off, but don’t let that dissuade you from popping in (we are at the far south end of campus in the Heating Plant building)

Great job, Jordan! I’m looking forward to sharing the Makerspace with such creative, driven people.

Wow! That is incredible! I plan to attend these classes, and will pursue the certificate! I am a graduate of the EET program, and I am surprised that this was not promoted more amongst the EET students! I was aware of the printer, but did not know about accessing these tools. I’m glad I now know, and this opportunity will be great for everyone!

I have an 11 year old son who is incredibly creative and very interested in 3rd printing. Is there opportunity for classes in his age range?

[…] can find common ground to collaborate on cool ideas. A computer science student is even making his own prosthetic hand at the […]

[…] All the Rage – This summer, Sylvania’s MakerSpace lab became a star. From student Jordan Nickerson fabricating his own prosthetic hand to Latinas learning about cool new technology in the Girls […]

[…] was made possible in part by Intel and has produced numerous feel good stories this summer – Jordan Nickerson’s new hand and Latinas learning about wearable […]

James, You knocked this one out of the park. I’m proud to say I hired you, young man. Doesn’t it seem like lifetimes ago we were checking people into the Al Gore for president event at one of the campuses, and we all dressed up because we thought, well, it’s not casual Friday so let’s look spiffy. On the other hand, Gore, the secret service and all the minions running around Vice President Gore were wearing polo shirts and dockers because they’d heard the Pacific Northwest was casual and wanted to “blend in,” so we were doing role reversals! One of many funny stories. Hope you’re following video Dave and his recent adventures …? Again, great story. Ironic it only got a silver at the district, but Gold at nationals.

Best, S